ABOUT US

Environmental Projects

ENVIRONMENTAL

ABOUT US

Environmental Projects from 2010 to 2019

Environmental stewardship and sustainability have become a focus of the Port of Port Angeles over the last decade. Per the Port’s current strategic plan, our mission is to “bring people, resources and industry together to foster economic prosperity and living wage jobs”. One way the Port executes the mission is by redeveloping contaminated industrial property and providing facilities and infrastructure for local businesses. These actions protect and improve environmental conditions in our community by providing facilities that meet or exceed environmental standards. Over the last 10 years, the Port has spent approximately $18.5 million in the projects improving our environmental performance. Check out our progress below!

Western Port Angeles Harbor Cleanup

Under an Agreed Order with the Washington State Departmentof Ecology (Ecology), the Port of Port Angeles has been working with other potentially liable persons (PLPs) to cleanup contamination in the sediments of Port Angeles Harbor caused by historic releases of hazardous substances. These hazardous substances include dioxins, PCBs, PAHs and metals released from industry and urban activities located around the Harbor over the last 100 years. This contamination can harm the wildlife and their habitat. Also, the Harbor has a long history as an important cultural area for the Klallam Indians.

The Port, other PLPs and Ecology have been working together to cleanup the Harbor. For information on the status of this project, click the Joint Announcement (Port & City) below:

April 2018 – Joint Announcement – Draft RI/FS submitted to Ecology

April 2019 – Joint Announcement – Revised Draft RI/FS submitted to Ecology

The Washington State Department of Ecology is the lead agency responsible for the overseeing the cleanup project. For more information on the Western Port Angeles Harbor click on the link to the right.

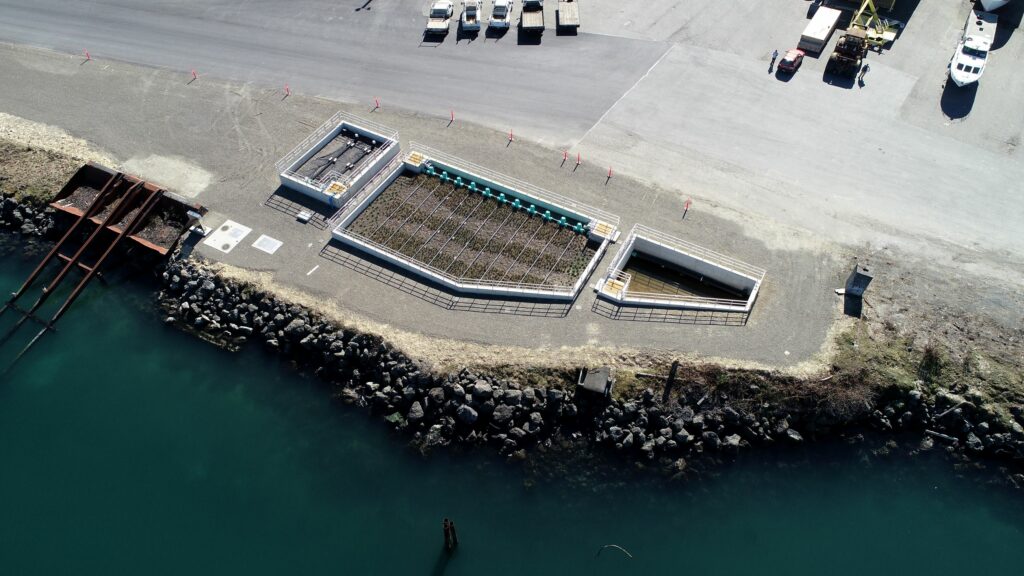

Marine Terminal Stormwater Rain Garden Design

The Port operates and managesfour deep-water marine terminals supporting the local economy numerous wood products and freight transportation enterprises. Washington’s waters are home to the endangered Southern Resident Orca Whale and threatened salmon species and Pacific Northwest marine facilities are subject to the most stringent stormwater quality limits in the nation. To address these concerns the Port developed a strategy identifying an effective low-impact, vegetated, biofiltration treatment approach, that was flexible enough to evolve with changing site uses and future regulations. Applying a judicious feasibility evaluation, bench-scale and pilot-scale testing, the Port designed and constructed an innovative three-stage natural treatment system that immediately met their water quality goals that continues to improve over time.

The Port of Port Angeles was the award recipient of the 2019 California Stormwater Quality Associations “Outstanding Industrial Stormwater BMP Implementation Project”.

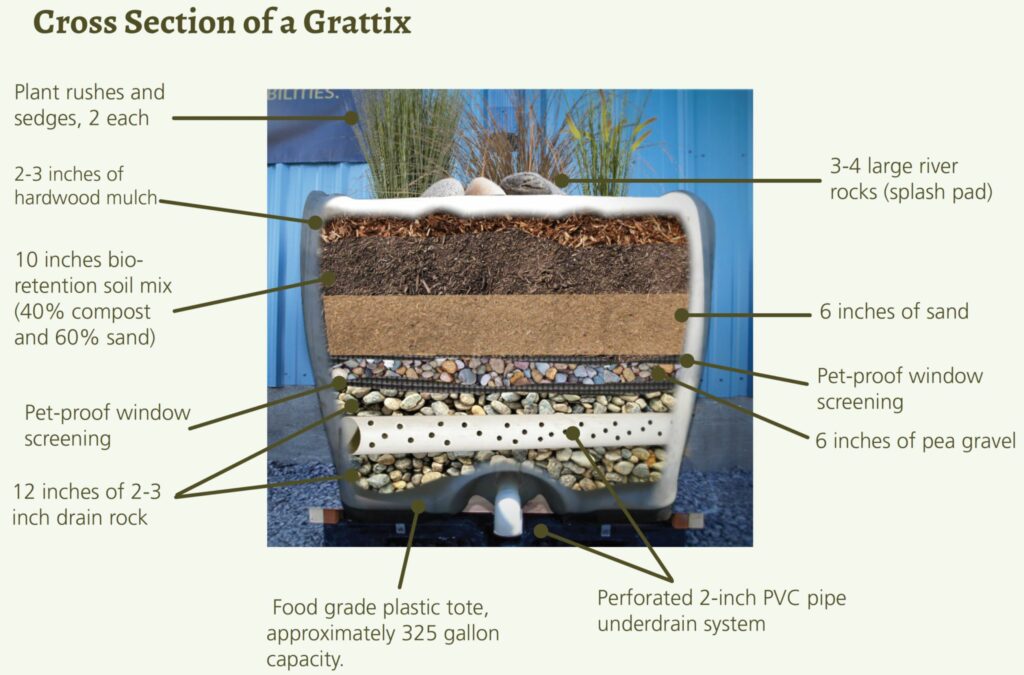

Rain Garden In a Box

The stormwater zinc concentration from an airport hangar was elevated so the Port installed three rain gardens in a box to remove zinc pollution.

The Port and many industries use zinc to protect rooftops from rust and degradation. But zinc hurts fish in local streams and can suffocate them when it gets into their gills. To address this issue the Port of Vancouver USA developed a rain garden in a box and called the system the Grattix. These systems remove up to 95% of the zinc in roof runoff and is a great low cost approach to treating roof runoff. The Port of Vancouver provides directions for the construction of these system at: https://www.portvanusa.com/resources/build-grattix/

Using these online instructions, in the winter of 2019, thePort of Port Angeles installed three “Grattix” boxes at the Port owned hangar leased by FedEx at the William R. Fairchild International Airport. This project was a success. Recent stormwater sampling detailed a 91% reduction in zinc concentrations.

Wash-Down Facility - Marine Trades Industrial Park

To provide environmentally sound boat washing facilities and grow the local marine trades sector, the Port constructed the Marine Trades Industrial Park (MTIP) Wash-down Facility in 2018. This is the Phase 1 of the MTIP redevelopment of the former K-PLY mill cleanup site. (Former Mill Site was cleaned up in 2016, read more about it below).

To keep boats and vessels shipshape, routine pressure washing is required. Pressure washing removes marine growth (barnacles, seaweed and other creatures) that impact the hull and boat performance. Along with the removal of sea creatures, pressure washing removes anti-fouling paints that contain high concentrations of copper and zinc. Because of these metals, the wash-water must be treated and then discharged to the city sewer. Prior to the Clean Water Act in the 1970s and implementation in the 1980s, this type of wash water would have discharged directly into storm or sewer drains.

The MTIP Wash-down facility collects wash water and treats it using a chemically enhanced sand filtration system. The chemical used is chitosan, a coagulant produced from crab and shrimp shells. Treated water is then discharged to the City sewer system. After the wash-pad is cleaned thoroughly by Port staff and not in use, stormwater generated at the facility is treated by a three stage bio-filtration treatment system prior to discharge to Port Angeles Harbor.

The combination of wastewater and stormwater treatment at the new MTIP Wash-down means this new facility is state of the art when it comes to protecting the marine environment.

Derelict Vessel Removal and Deconstruction

As the owner of two marinas, the Port of Port Angeles removes and demolishes derelict boats on a routine basis. Removing these vessels protects the health and safety of other marina users and the environment. Derelict or abandoned vessels are more than an eyesore; they can be a real threat. Pollution associated with vessels poses a risk to people and wildlife. Contamination is mainly caused by fuel spills, which occur when vessels sink or breakup.

If a boat is abandoned in the marina or washes ashore onto Port property, the first step is removing the vessel safely from the water or nearshore environment. This is accomplished by contracting with a professional marina salvage company and using the Port’s heavy lift piers located at the Port Boat Yard (75-ton pier) or the Port Angeles Marine Trades Industrial Park (500-ton pier). Once on dry land the Port removes all hazardous materials (fuel, oil, oily bilge water, antifreeze, batteries and asbestos). At the same time the Port notifies the owner of the boat and moves through the process of taking ownership if the owner is not responsible and/or responsive. After taking ownership, the Port’s facilities maintenance crews dismantle and dispose of the boat using an excavator in the Boat Yard or at the Marine Trades Industrial Park. The location for this work is key, because both facilities have the appropriate stormwater and wastewater controls/treatment in place to protect the environment.

Following these steps, the Port has demolished 12 boats over the last 6 years at a cost of $80,000. The boats have ranged in size from 20 to 60 feet in length. Through the Washington State Department of Natural Resources Derelict Vessel Removal Program, the Port seeks 90% reimbursement for the cost of this work. Funding for this State program is generated by surcharges on annual vessel registration.

The removal and deconstruction of derelict vessels is part of owning two public marinas. The Port performs this operation efficiently, economically and in an environmentally sound way protecting the public, the community’s waterfront facilities and the marine environment.

Creosote Pile Removal - Port Angeles Harbor

In an ongoing process to maintain our waterfront facilities and improve environmental quality the Port is programmatically replacing creosote treated pilings with steel or concrete pilings. In 2014, the Port received a US Army Corps of Engineers 10-year programmatic maintenance permit to maintain and upgrade our marine terminal facilities. Through the implementation of a pier maintenance plan and as budget/grant funding allows, the Port has replaced hundreds of creosote pilings at our Terminal 1 and 3 facilities. The removal of these creosote treated pilings reduces a source of polycyclic aromatic hydrocarbons (PAHs) in to Port Angeles Harbor. PAHs absorb readily into marine sediments and enter the food chain.

Creosote treated pilings and timbers were used for more than 100 years throughout the Puget Sound, as fundamental structural elements in marine cargo and transportation infrastructure. Present day marine facility piers and docks have replaced creosote construction with inert steel and concrete pilings, and in many instances fender systems requiring no piling have been installed. This benefits wildlife since it requires less structural pilings, less over-water coverage and removes creosote treated pilings from the marine environment.

The Port’s Terminal 1 was constructed in 1920s and Terminal 3 in the 1960s. Combined the marine terminals are supported by thousands of creosote treated pilings. Since 2014 the Port has removed 250+ creosote treated pilings from Terminals 1 & 3 at a cost of $4 Million. In 2019 and beyond, the Port will continue to remove creosote pilings as we maintain our community’s waterfront infrastructure.

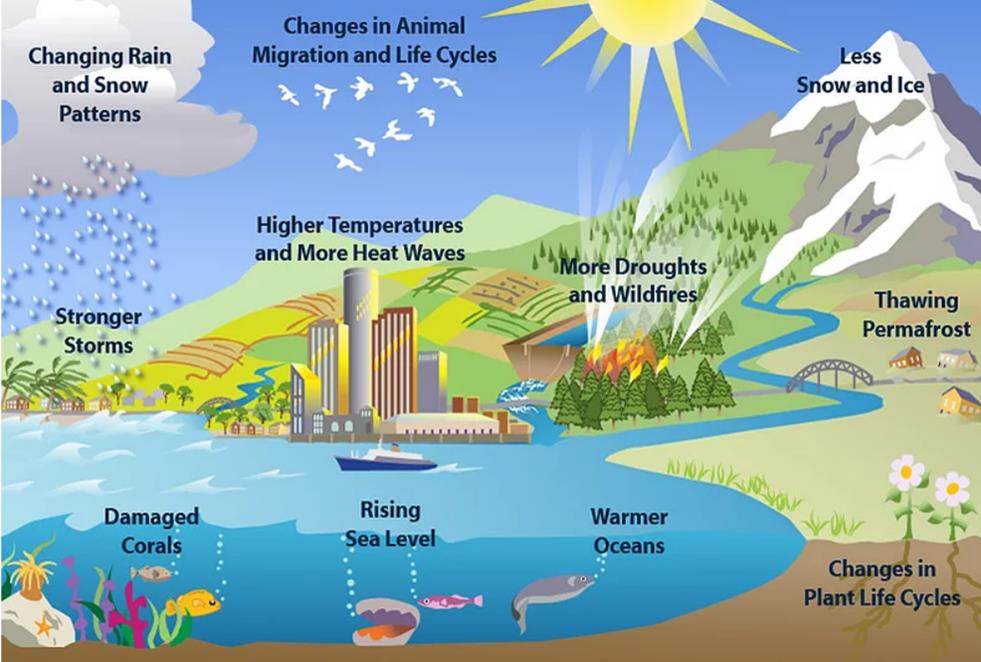

Climate Change Preparedness Plan

In 2014 and 2015, the Port participated in the development of a Climate Change Preparedness Plan for the North Olympic Peninsula. This planning process was headed by the North Olympic Development Council. With funding provided by the Washington State Departments of Ecology and Commerce. The development of the plan was a collaborative effort of more than 175 people representing many different government agencies, tribes, and local business. Climate change poses a variety of threats to the North Olympic Peninsula , including the potential to increase air temperatures, change precipitation patterns, reduce snowpack, and alter the biochemical cycle of the forests and oceans. This project aims to reduce the risks due to climate change through the detailed assessment of climate related vulnerabilities and the creation of a Climate Preparedness Plan. Download the plan here.

The Plan details:

- A compilation of detailed local observations and projections of climate change using best available science

- A prioritization of highly sensitive or vulnerable resources and locations

- A prioritized set of adaptation strategies and actions based on both the science and the knowledge of local stakeholders

From the participation in this project the Port realizes that adaptive strategies such as retrofitted shoreline armoring in some areas and soft defense strategies in other locations will be critical in dealing with sea level rise over the next 50 years.

Dungeness Piling Removal

In October 2018, the North Olympic Salmon Coalition (NOSC), utilizing state grant funding, removed 171 creosote treated timber piles from the former Dungeness Wharf. The removal of these creosote treated pilings reduces a source of polycyclic aromatic hydrocarbons (PAHs) to Dungeness Bay. PAHs can harm marine species. These pilings were on Port owned tidelands in Dungeness Bay. The original Wharf was constructed in 1890 and was used to ship the agricultural products of the Dungeness Valley to Seattle and other west coast markets. The Port purchased the property and the wharf in 1925 and it was operated into the 1940s. Since that time the structure slowly deteriorated until there was 171 pilings remaining. In 2013, the NOSC approached the Port regarding the removal of the remaining pilings connected to their Three Crabs Estuarine and Nearshore Restoration Project. In 2017, the Port Commission authorized NOSC to remove the pilings through an access agreement that required the NOSC to preserve or replace pilings for the Olympic Peninsula Audubon Society’s purple martin next boxes that have been on the pilings for years. The Port thanks the NOSC for taking on this project to protect water quality and preserve the nesting boxes for the purple martins.

Sequim Gazette article on this Project

Shore Power

In 2009 the Port, in partnership with the City of Port Angeles, installed two 1500KVA transformers at Marine Terminal 1 to provide shore power for ships at berth. When a ship is moored, its electricity can be supplied running its boilers, which burn diesel fuel, or by hooking up to shore side power and shutting down its boilers and generators. The latter is known as the vessel going “cold-iron” which has many advantages:

- The environment wins because there is a reduction in air emissions from ships moored at the Port dock. For 80 tanker days at the dock, this is a reduction of 2300 metric tons of greenhouse house, gas carbon dioxide.

- The shipping company benefits from reduced operational costs, reduced use of diesel fuel, and less wear and tear on the ship’s engines.

- Revenue to Port and City from the sale of power.

- The community benefits from cleaner air and increased ship business.

Boatyard Stormwater Treatment

In 2014 the Port installed a biofiltration and infiltration (rain garden) to treat stormwater generated at the Port Angeles Boat Yard. The Port Angeles Boatyard is a busy and compact “do-it-yourself” yard, were the public can pressure wash, repair and maintain their boats. These activities result in pollutants such as lead, copper and zinc entering the yards stormwater discharge. To reduce pollution in boat yard stormwater Port staff designed, permitted and constructed a rain garden to filter and infiltrate boatyard stormwater. This system treats approximately 800,000 gallons of stormwater a year.

Composites Recycling Technology Center (CRTC)

In 2015 the Port constructed the CRTC with federal, state and local funding. The CRTC develops and demonstrates new product manufacturing by using recycled waste carbon fiber pre-preg. Pre-preg is a carbon fiber with pre-applied (impregnated) epoxy resin. The CRTC is a non-profit whose purpose is to spur growth of environmentally-positive, high-tech composites manufacturing in Clallam County. The Washington State Department of Ecology estimates that two million pounds of carbon fiber composites scrap are generated annually in this state. The CRTC anticipates diverting as much as 1.4 million pounds/year of this high value carbon fiber material by Year 5. In addition to recycling carbon fiber, the facility utilizes a HVAC system with variable flow refrigerants and solar photovoltaic panels to improve energy efficiency.

KPly Cleanup

In 2016 the Port completed the environmental cleanup of the former KPly Mill Site. The site has a long and rich history of plywood mills and jobs for the people of Clallam County. However during the plywood mill years, the operations of those mills and adjacent bulk fuel plants, contaminated the groundwater and the soil with petroleum hydrocarbons. This cleanup project begin with the demolition of the mill structures in 2012 and was completed by excavating 50,000 tons of contaminated soil in 2016, at a cost of $11.8 million. The Port was reimbursed for this project through Washington State Department of Ecology Grant Funding and contributions from Port insurance and Potentially Liable Persons (PLPs). In 2018 the Port begin to redevelop the site as a Marine Trades Industrial Park.

Fluorescent to LED

In 2016 the Port begin switching fluorescent light to LED bulbs throughout the Port facilities. LED bulbs use 20% less energy and last 13 times longer than fluorescent bulbs. Long term sustainability is import to the Port and energy efficiency isimport. This work begin with new efficient LED lighting at the Port MarineTerminals 1 and 3 and was followed by the install of LED lighting at theMulti-Tenant Industrial Building at the North Airport Industrial Park. The City of Port Angeles energy efficiency rebate program, has assisted with this ongoing retrofit.

Clean Marina

In the summer of 2018 the Port Angeles Boat Haven and John Wayne Marina were certified under the Clean Marina program. Which is an incentive-based certification program in which marinas assess their operations and implement improvements to better protect the environment. Clean Marina Washington provides marina best management practices (BMPs) that are practical and affordable actions that can reduce pollution at the source. By effectively implementing BMPs, marinas and marina tenants may be able to avoid more expensive and restrictive measures being placed on the boating public by regulatory agencies. Under this program the Port will implement additional programs such as marina recycling and tenant education on invasive marine species.

In the summer of 2018 the Port Angeles Boat Haven and John Wayne Marina were certified under the Clean Marina program. Which is an incentive-based certification program in which marinas assess their operations and implement improvements to better protect the environment. Clean Marina Washington provides marina best management practices (BMPs) that are practical and affordable actions that can reduce pollution at the source. By effectively implementing BMPs, marinas and marina tenants may be able to avoid more expensive and restrictive measures being placed on the boating public by regulatory agencies. Under this program the Port will implement additional programs such as marina recycling and tenant education on invasive marine species.

Stormwater Treatment at Marine Terminal & Log Yard

In 2018 the Port installed two separate stormwater treatment systems at the Port Marine Terminal and the Port Log Yard. Port Angeles was built on timber and the Port still exports millions of board feet of logs around the world. Due mostly to debarking activities that ensure pests are not transported across oceans, stormwater runoff from the Port’s log yard and export terminal carried very high pollutant loads that are exceptionally difficult to control. To improve water quality and comply with the most stringent stormwater regulations in the nation the Port installed new conveyance, asphalt paving and advanced treatment at both the Port Marine Terminal 3 and Log Yard. At the marine terminal a combination of asphalt paving and a large biofiltration system (rain garden) was installed to filter pollution from stormwater generated by truck traffic and log loading. At the Log Yard options were limited because of proximity to cultural resources so a chemically enhances sand filtration system was installed. This system removes pollutants (sediment & wood debris) by mixing a coagulant in the stormwater and then filtering out sediment utilizing a system of sand filters. Both of these systems protect water and sediment quality in Port Angeles Harbor.

Contact Us

Jesse Waknitz

Environmental Manager

Email Jesse Waknitz

Phone: 360-417-3452